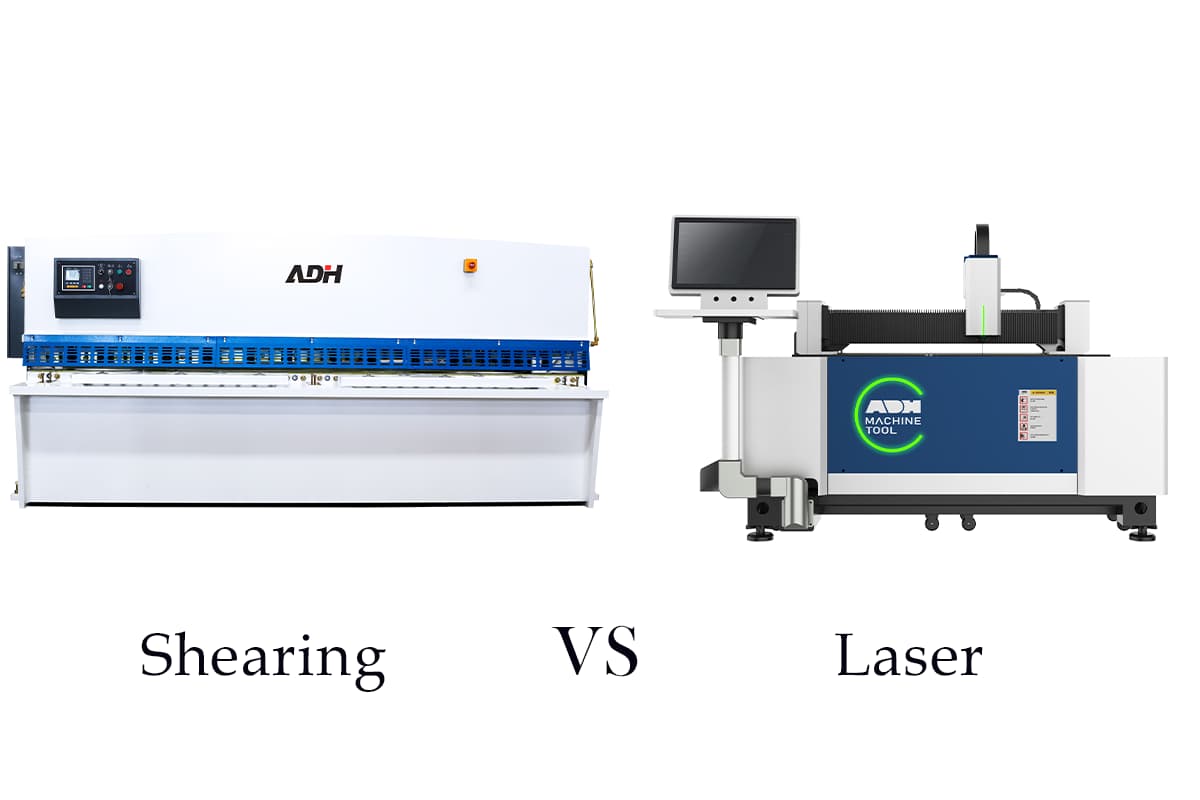

In sheet metal processing and manufacturing, choosing the right machinery is crucial for efficiency, productivity and product quality.  Machinery is widely used including shearing machines, flame-cutting, plasma cutting, laser cutting equipment, etc. Two prominent sheet metal processing technologies in this field are hydraulic shearing machines and laser cutting machines. While both are integral to cutting and shaping metal, they each have distinct advantages and disadvantages. One of the significant advantages of shearing machines is their ability to quickly process materials. Understanding the capabilities and limitations of both shearing machines and laser cutting technology allows businesses to optimize their production processes, reduce costs, and increase productivity. It's essential to conduct a comparative analysis of hydraulic shearing machines vs. laser cutting machines, including cost, precision, material versatility, speed and efficiency, maintenance and operational costs, automation and ease of use, environmental impact, and long-term sustainability, to understand their respective strengths and weaknesses across various operational contexts. Hydraulic Shearing Machines: Laser Cutting Machines: Hydraulic Shearing Machines: Laser Cutting Machines: Hydraulic Shearing Machines: Laser Cutting Machines: Hydraulic Shearing Machines: Laser Cutting Machines: Hydraulic Shearing Machines: Laser Cutting Machines: Hydraulic Shearing Machines: Laser Cutting Machines: Hydraulic Shearing Machines: Laser Cutting Machines: Hydraulic Shearing Machines: Laser Cutting Machines: Hydraulic Shearing Machines: Laser Cutting Machines: Hydraulic shearing machines are frequently used for cutting large metal sheets to manufacture car body parts, chassis, and other structural components. Their high-speed cutting capabilities make them ideal for processing the thick metal sheets often required in automotive manufacturing. Laser cutting machines excel in producing intricate and precise components required for modern vehicles. They are used for cutting and shaping metal parts, including body panels, engine components, and interior features. The precision and minimal material wastage offered by laser cutting are particularly beneficial for creating complex and lightweight automotive parts. Hydraulic shearing machines are used for cutting large sections of metal, such as aluminum and titanium sheets, used in constructing aircraft bodies and structural components. Their ability to handle thick materials efficiently makes them suitable for these heavy-duty applications. Laser cutting machines provide high precision and can be used to cut a wide range of materials, including metals, composites, and reflective materials. They are used for producing high-precision components such as turbine blades, aircraft skins, and intricate structural parts. In the construction industry, hydraulic shearing machines are employed for cutting metal components used in building projects, such as steel beams, metal sheets, and rebar. Their robust construction and high-speed cutting capabilities make them ideal for processing large volumes of construction materials efficiently. Laser cutting machines are used for creating detailed metal components, decorative elements, and customized architectural features. The precision and versatility of laser cutting allow for the production of intricate designs and high-quality finishes. While less common in the electronics industry due to their limited precision, hydraulic shearing machines can still be used for cutting metal enclosures and larger components that do not require intricate detailing. Laser cutting machines are highly valued in the electronics industry for their ability to produce small, intricate parts with high precision. They are used for cutting circuit boards, connectors, and various electronic components, ensuring accuracy and minimal material wastage. In custom manufacturing, hydraulic shearing machines are used for cutting a variety of metal materials to specific sizes and shapes. Their versatility and power make them suitable for handling diverse projects, from industrial machinery parts to unique architectural elements. Custom manufacturing greatly benefits from laser cutting machines due to their ability to produce detailed and complex designs. They are used for creating customized products, prototypes, and artistic pieces with high precision and quality. Hydraulic shearing machines play a pivotal role in the metal fabrication industry, allowing for precise cutting of material, using a hydraulic system to exert shear force on a blade, and performing a guillotine-like shearing action on the metal. They are cost-effective and suitable for high-speed cutting of thick metal sheets but lack the precision and versatility of laser cutting machines. In contrast, laser cutting machines utilize a high-powered laser beam, directed by CNC (Computer Numerical Control) systems, to make highly precise cuts in various materials. These cutting tools ideal for intricate designs and provide minimal material wastage but come with higher initial and operational costs. Additionally, laser cutting is a non-contact process, which reduces the risk of material contamination and tool wear. Comparison Table: Hydraulic shearing machines are generally more cost-effective for small-scale operations due to their lower initial investment and simpler maintenance requirements. They are ideal for businesses that primarily need to cut thick metal sheets and do not require the high precision offered by laser cutting machines. While laser cutting machines are highly versatile and can cut a wide range of materials, including metals, plastics, wood, and composites, they are not suitable for all materials. Highly reflective materials, such as copper and aluminum, can be challenging, and very thick materials (typically beyond 25 mm) may not be efficiently cut by lasers. Specialized techniques and higher power settings can mitigate some of these limitations. Hydraulic shearing machines require regular maintenance to ensure optimal performance. Maintenance tasks include: Regular maintenance prevents mechanical failures and extends the machine's lifespan. Laser cutting machines are significantly more precise than hydraulic shearing machines. They can achieve intricate designs with tight tolerances and minimal kerf sizes, making them suitable for applications requiring high sheet metal cutting accuracy. Hydraulic shearing machines, while effective for straightforward cuts, lack the precision needed for detailed and complex shapes. Yes, laser cutting machines can pose safety concerns if not properly managed: Hydraulic shearing machines are typically used in: The initial investment for laser cutting machines is significantly higher than that for hydraulic shearing machines. Laser cutters require advanced technology and precision engineering, leading to higher costs for purchase and setup. In contrast, hydraulic shearing machines are more affordable during the shearing process, making them a more accessible option for businesses with limited budgets or those focusing on high-speed cutting of thick metal sheets.

Sometimes you need a spare part for your equipment, and with thousands of spare parts, we have got you covered. Our extensive global service network not only means prompt delivery, but also an after sales network you can rely on. Ruican is a professional Auto Parts manufacturer, all the parts including Engine Spare Parts, Wheel Hub , break system accessories, and Trailer Hook etc.

Brake System Accessories,Brake System Parts,Automotive Performance Brake System Parts,Auto Brake System Parts,Car Brake System Accessories NINGBO CITY YINZHOU RUICAN MACHINERY CO.,LTD , https://www.nbsandcasting.comI. Introduction

II. Hydraulic Shearing Machines vs. Laser Cutting Machines Analysis

Cutting Capabilities Matrix

Thickness Range 0.5-40mm 0.5-25mm Cutting Speed 8-22 strokes/min Up to 20m/min Precision ±0.1mm ±0.05mm Power Requirements 5.5-7.5 KW 500W-20kW Cost Comparison

Initial Investment

Operational Costs

Precision and Accuracy

Material Versatility

Speed and Efficiency

Maintenance and Operational Costs

Automation and Ease of Use

Environmental Impact and Long-Term Sustainability

Innovative Applications and Emerging Trends

III. Hydraulic Shearing Machines vs. Laser Cutting Machines Comparison Table

Aspect Hydraulic Shearing Machines Laser Cutting Machines Types Guillotine shearing machines; Swing beam shearing machines CO2 laser cutting machines; Fiber laser cutting machines; Nd: YAG laser cutting machines Working Principle The utilization of hydraulic power to exert substantial pressure to achieve the cutting process Uses a high-powered laser beam focused into a small spot to melt, burn, or vaporize material. Cost Lower initial investment and operational costs. High upfront costs for purchase, installation, and training. Operation & Maintenance Simple to operate with low maintenance requirements. Requires skilled operators and frequent maintenance, especially for CO₂ lasers. Cutting Speed Fast for thick sheet metal sheets. High-speed cutting, especially for thin materials. Precision Lower precision; not suitable for intricate designs. Extremely high precision with minimal kerf width. Material Versatility Best suited for metal sheets; struggles with non-metallic materials or very thick metals. Can cut various materials, including metals, plastics, wood, and fabrics. Material Deformation Cutting may cause burrs, warping, or imperfections, requiring post-processing. Minimal material deformation with smooth edges and minimal finishing required. Energy Efficiency More energy-efficient with lower power consumption. Higher energy consumption, particularly for CO₂ lasers. Noise & Heat Generation Generates noise and heat, requiring cooling and noise reduction systems. Generally quieter but still requires fume extraction systems for certain materials. Environmental Impact Uses hydraulic oil, which requires proper disposal; otherwise environmentally friendly. Produces minimal waste, but cutting certain plastics may emit harmful gases. Safety Advanced safety features (emergency stops, guards) but requires adherence to safety protocols. Fume extraction and safety protocols are essential; exposure to the laser beam is hazardous. Cutting Capability Limited to 2D cutting of metal sheets. Can handle both 2D and limited 3D applications but not as well as waterjet cutters. Footprint and Size Compact design makes it easier to integrate into production lines. Larger machines with limited bed sizes for cutting large materials. Automation & Integration Basic automation available. Easily integrated with CAD/CAM systems for automated design and manufacturing. Tooling Costs Requires physical tools but has lower replacement costs. No tooling costs due to the contactless nature of laser cutting. Long-Term Costs Lower operational costs over time. Higher maintenance and operational costs accumulate over time. IV. Industry-Specific Applications

Automotive Industry

Hydraulic Shearing Machines

Laser Cutting Machines

Aerospace Industry

Hydraulic Shearing Machines

Laser Cutting Machines

Construction Industry

Hydraulic Shearing Machines

Laser Cutting Machines

Electronics Industry

Hydraulic Shearing Machines

Laser Cutting Machines

Custom Manufacturing

Hydraulic Shearing Machines

Laser Cutting Machines

V. Frequently Asked Questions

1. What are the main differences between hydraulic shearing machines and laser cutting machines?

Feature Hydraulic Shearing Machine Laser Cutting Machine Initial Cost Lower Higher Precision Moderate High Material Versatility Primarily metal sheets Various materials including metals, plastics, wood Thickness Capability Suitable for thick materials Limited effectiveness on very thick materials (>25mm) Speed High for thick materials Varies; slower for intricate cuts Maintenance Simpler More complex Operational Cost Lower Higher Applications Automotive, construction, shipbuilding Electronics, aerospace, custom fabrication 2. Which machine is more cost-effective for small-scale operations?

3. Can laser cutting machines cut all types of materials?

4. What kind of maintenance is required for hydraulic shearing machines?

5. How does the precision of laser cutting compare to hydraulic shearing?

6. Are there any safety concerns associated with using laser cutting machines?

7. What are the typical applications of hydraulic shearing machines in the industry?

8. How does the initial investment of laser cutting machines compare to hydraulic shearing machines?