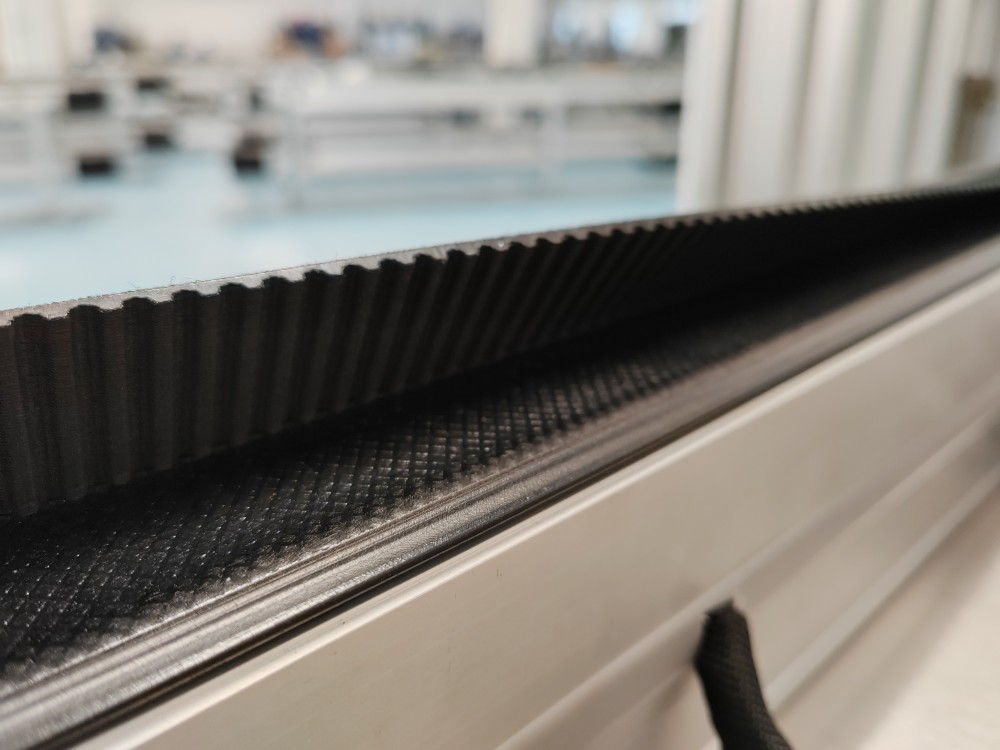

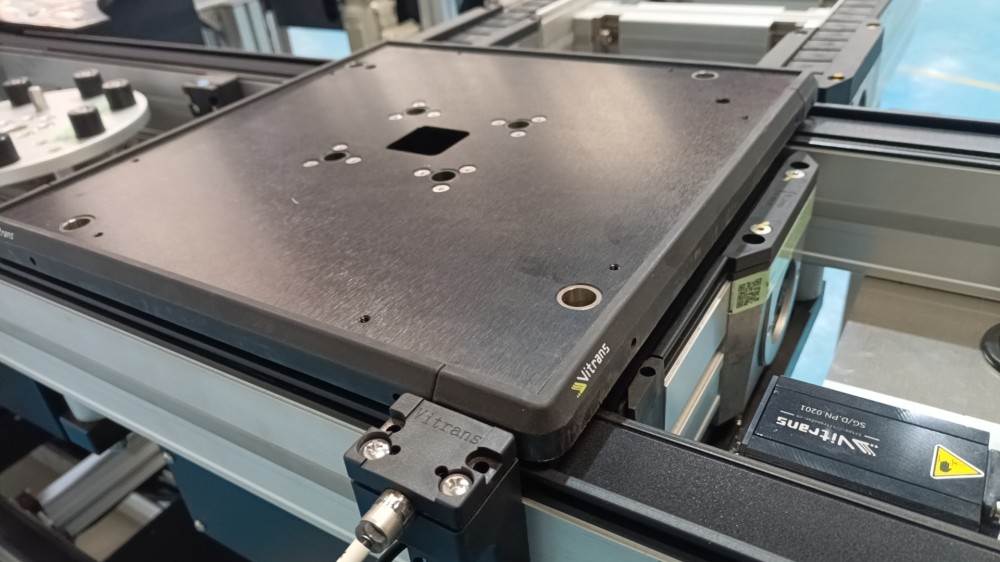

Timing Belt Conveyor: Precision and Efficiency Unleashed In the realm of conveyor systems, the integration of timing belt conveyors marks a paradigm shift towards precision and efficiency. As a critical component, timing belt conveyors redefine automated processes, ensuring seamless material handling across various applications. Precision Timing in Automation The heartbeat of automated conveyors, timing belt conveyors play a pivotal role in maintaining precision throughout the material handling process. This is especially crucial in assembly line conveyors and factory setups, where accurate synchronization is essential for the success of automated operations. Versatile Handling Solutions Timing belt conveyors offer versatility in handling a myriad of materials. From tray conveyors to battery conveyors, their adaptability enhances the efficiency of production lines. The timing belt, in conjunction with conveyor motors, facilitates controlled and synchronized movements, ensuring optimal production flow. Engineering Excellence and Design Precision in design sets timing belt conveyors apart. The intricate engineering of these conveyors, coupled with conveyor positioning technology, guarantees accurate location and rotation of materials. The result is a conveyor system that aligns with the unique needs of each industry, contributing to streamlined production processes. Timing Belt Conveyor in Vitrans Systems Vitrans pioneers the use of timing belt conveyors in conveyor system designs, setting new standards in industrial automation. Compared to competitors like Bosch, Dorner, and Flexlink, Vitrans excels not only in quality but also in affordability. Our timing belt conveyor systems showcase a perfect blend of engineering excellence and cost-effectiveness. Vitrans Advantage: Precision and Competitive Pricing Choosing Vitrans means opting for a conveyor system that prioritizes precision and efficiency. The timing belt conveyor designs ensure optimal material transport, positioning, and rotation, contributing to an elevated production experience. Vitrans stands out with competitive pricing, providing manufacturers with an advantageous blend of quality and affordability. Elevate Efficiency with Vitrans Timing Belt Conveyors In conclusion, the application of timing belt conveyors signifies a significant advancement in conveyor system technology. Vitrans, as a leading manufacturer, propels industrial automation forward by incorporating precision timing into its conveyor designs. Choose Vitrans for a conveyor system that not only meets but exceeds industry standards, providing an unparalleled combination of precision, efficiency, and affordability. Timing belt conveyor,belt conveyor,pallet conveyor,conveyor system,conveyor,Vitrans Automated Production Line Pallet Conveyor System Vitrans Automation Equipment Co.,Ltd , https://www.vitrans-automatic.com

Configuration: It adopts parts with high performance and the precision and suitable structure and design.Without auxiliary parts, the cut pipe section is flat and smooth, which really realized the flash cutting of pipes of small caliber and solved the problem of hard cutting of high-speed production.

Advantages for dust free cutterÂ

(1). Imported PLC controller

(2). Sawdust powerful attraction device

(3). Suitable for high-speed cutting of various small caliber tubing

(4). Flat and lubricous in cutting face,no need for grinding and processing after pipe cutting.

(5). Adopt international advanced technology,imported PLC intelligentized controlling system.

(6). It is one of necessary auxiliary machines in the large or middle plastic pipe extrusion lines.

Â

Featured of automatic pvc pipe cutters:

(1). Imported inverter, PLC program controller controls all mechanical drives.Â

(2). It can product movements of motors, electrical appliances.

(3). It can balance weight in cutting, and make it more stable.Â

(4). Its applicability is wide and its usages are convent

Â

Â

Cutting type

Pipe range(mm)

Cutting way

Control way

No-dust cutting machine

Φ16-Φ630

Saw blade

PLC

Lift knife cutting machine

Φ20-Φ110

Saw blade

PLC

Hydraulic planet cutting machine

Φ63-Φ2000

Hydraulic planet

PLC

Â

Vitrans Automated Production Line Pallet Conveyor System

Professional customized production line Conveyor and assembly line conveyor, automated, modular, make your production and andassembly more efficient and upgrade your production line easier. No matter what the product is, it will increase your production line capacity.

Hauling Machine and Cutter for PVC PE PPR PP

Condition: New

Power: 380V 50Hz

Cutting Way: Manual/Automatic

Color: Customers

Inverter Brand: Switzerland ABB

Cutting Type: Saw Blade

Electrical Brand: Schneider

Height: Customers

Max Cutting Thickness: Different

Range: 16mm-2000mm

Trademark: SWD

Transport Package: Export Standard

Specification: 16mm-2000mm

Origin: China Siweida Machinery

HS Code: 84778000

Plastic PVC PPRÂ PE PP Pipe Cutting Machine