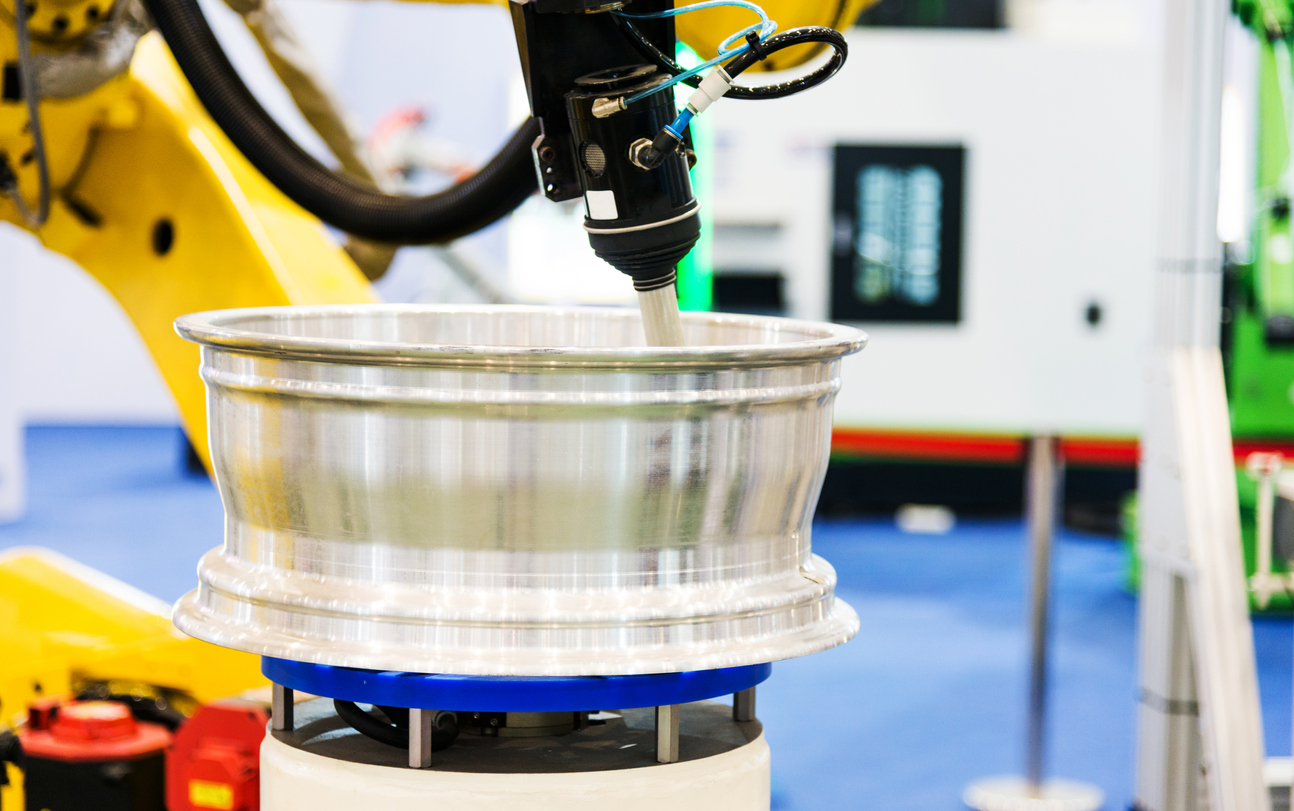

Robotic welding has revolutionized manufacturing by significantly boosting productivity and consistency compared to traditional manual methods. However, even after installation and programming, there's always room for improvement in terms of cost efficiency and performance. The key is to continuously optimize your robotic welding system to achieve better results with fewer resources. There are several effective strategies that can help reduce the overall cost of robotic welding operations while maintaining or even increasing output. These tips not only improve efficiency but also support long-term sustainability and profitability. Robotic welding systems are sophisticated pieces of equipment that require careful management and maintenance. By focusing on cost-saving practices, manufacturers can enhance productivity and reduce unnecessary expenses. Here are seven practical ways to cut costs without compromising quality: Utilize welding peripherals effectively: Components like reamers, contact tips, wire cutters, and inspection tools play a vital role in ensuring smooth operation. Neglecting these can lead to inefficiencies, increased downtime, and higher repair costs. Make sure all peripherals are used to their full potential. Optimize filler metal packaging: Frequent changes of filler metal packages can cause production delays. By selecting larger, more efficient packaging sizes, you can reduce the number of changeovers, which in turn increases uptime and lowers labor costs. Ensure proper wire feeding: Poor wire feeding is a common issue that can lead to machine stoppages and damage. Regularly inspect and maintain wire feeding systems to prevent costly interruptions and extend equipment life. Extend the life of contact tips: Contact tips wear out over time, so regular cleaning and replacement are essential. Keeping them in good condition reduces the frequency of replacements, saving both time and money. Protect reamer blades: Damaged cutting blades in reamers can slow down production and increase maintenance costs. Proper alignment of nozzles and regular inspections can help prevent blade breakage and ensure consistent performance. Invest in operator training: Well-trained operators are more efficient and less likely to make mistakes. Many integrators offer comprehensive training programs that cover safety, troubleshooting, and best practices, helping maximize robot performance and minimize errors. Implement a preventive maintenance schedule: Routine maintenance is crucial for keeping equipment running smoothly. A well-structured maintenance plan helps identify issues before they become major problems, reducing unexpected downtime and repair costs. By following these strategies, manufacturers can significantly lower the cost of robotic welding while maintaining high-quality output. It’s all about making smart decisions and investing in the right tools and training. With the right approach, robotic welding can deliver maximum value and long-term benefits. If you're interested in learning more about how to optimize your robotic welding setup, explore Genesis Systems' advanced integration services designed to boost efficiency and reduce operational costs. Plastic Weatherstrips,Plastic Car Door Weather Strip,Weather Strip For Cars,Door Weather Strip For Car HE BEI HONGAN AUTOMOBILE AND MOTORCYCLE FITTINGS CO.,LTD , https://www.honganproduct.com7 Essential Tips for Reducing the Cost of Robotic Welding Operations

How to Lower Costs in Robotic Welding Systems

7 Tips for Improving the Cost of Robotic Welding Operations

Our PVC seal is a high-quality product designed to provide a secure and watertight seal for various applications. Made from durable PVC material, it offers excellent resistance to extreme weather conditions, chemicals, and UV radiation.

This seal is specifically designed for use in plumbing, construction, and electrical installations. It effectively prevents leaks, moisture, and air infiltration, ensuring optimal performance and longevity of the system.

With its easy installation process, our PVC seal can be quickly and conveniently applied to various surfaces, including pipes, joints, and fittings. Its flexible nature allows for a snug fit, accommodating slight variations in size and shape.

The PVC seal is also highly versatile, suitable for both indoor and outdoor use. It can be used in residential, commercial, and industrial settings, providing reliable sealing solutions in a wide range of applications.

In addition to its functional benefits, our PVC seal is aesthetically pleasing, available in a variety of colors to match different décor styles. Its smooth finish adds a professional touch to any installation.

Overall, our PVC seal is a reliable and efficient product that ensures a tight and durable seal, making it an essential component for any plumbing, construction, or electrical project.