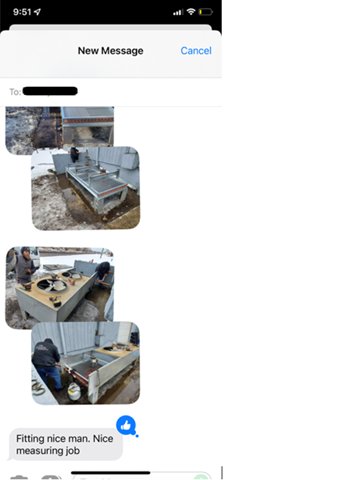

Join me, Chris Wright, the Chicago-based Account Manager, as I head over to the P&W Foundry in Plano, Illinois. There, I found myself knee-deep in a high-stakes project involving a critical Liebert® condensing unit. Just recently, we received an urgent call from the P&W Foundry in Plano, Illinois, requesting a replacement coil for their Liebert® condensing unit. This particular unit was crucial for maintaining operations on a production floor that specialized in creating time-sensitive components for the U.S. Navy. With no room for downtime, we knew we had to act fast. As soon as we got the call, we set out to measure the existing unit to ensure a precise replacement. Given that none of the paired equipment was being swapped out, it was absolutely vital to replicate the coil’s circuitry (number of feeds), fin density, and piping connections exactly to maintain the same level of performance. Despite the coil being large, it was conveniently accessible, allowing us to size it accurately without any major hitches. This coil had several non-standard features, but nothing I hadn't encountered before in my fieldwork. For instance, the copper connections extended out of the bottom of the headers. We had to ensure the new design matched this layout precisely to facilitate a seamless swap-out in the field. Additionally, the flanges on the coil were constructed non-standardly, requiring an extra bend on each of the air-entry-side plate flanges. This adjustment was made to provide added stability to the slab coil, which rested on four pillars. With some quick sketches and detailed notes, we were able to customize everything to perfection. The client put this coil on a 5-day production schedule, and they were thrilled with how smoothly the installation went! By the end of the week, our customer was back up and running, and they couldn’t have been happier with the performance of the replacement coil. Rubber Pipe Flange Gaskets,Silicone Fabric Insulation Jacket,Cloth Insulation Gasket For Pipe,Flange Ring Joint Gasket Taixing Yingxing Composite Material Co.,Ltd , https://www.ptfecnyx.comSite Bite: Replacing the Coil in a Liebert® Condensing Unit

Written by: Chris Wright

Nationwide Coils Account Manager, Chicago