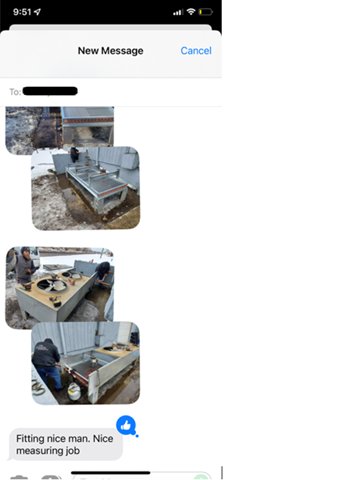

Join me, Chris Wright, Chicago-based Account Manager, as I head over to the P&W Foundry in Plano, Illinois. It turned out to be quite the challenge when we discovered we needed to measure for a critical replacement job. Just the other day, we received an emergency call from the P&W Foundry in Plano, Illinois. They urgently needed us to fabricate a replacement coil for their Liebert® condensing unit. This unit was crucial for maintaining operations on their production floor, which specializes in creating time-sensitive components for the U.S. Navy. Given the importance of keeping the unit operational, there was no room for delay. We packed our tools and headed straight to the site the very same day to take precise measurements. Since neither the paired equipment nor the existing coil was being replaced, it was essential to replicate the coil's circuitry (the number of feeds), fin density, and piping connections exactly to ensure seamless performance. Despite the coil's size, it was surprisingly accessible, and the sizing process went smoothly. There were several non-standard features on this coil, but nothing I hadn't encountered in my years of experience in the field. The copper connections extended below the headers, meaning we had to carefully match this design to ensure a straightforward installation. Additionally, the flanges on the coil were uniquely constructed, requiring an extra bend on each of the entering air-side plate flanges. This modification provided added stability to the slab coil, which rested on four support pillars. With a few sketches and thorough notes, we managed to customize every detail to perfection. The customer placed the coil on a 5-day production schedule, and they were thrilled with how straightforward the installation turned out to be! By the end of the week, our client was back up and running, satisfied with the performance of the new coil. Taixing Yingxing Composite Material Co.,Ltd , https://www.ptfecnyx.comSite Bite: Replacing the Coil in a Liebert® Condensing Unit

Written by: Chris Wright

Nationwide Coils Account Manager, Chicago